Our story

About ROKR

ROKR is a sub-brand of Robotime Technology (Suzhou) Co., Ltd, which is a Chinese toy brand that focuses on designing, manufacturing and selling wooden puzzles and educational toys for kids and adults. It integrates the beauty of machinery and scientific exploration to meet the eager-to-learn spirit of the intellectual enthusiasts who advocate science and technology, creativity, and freedom.

Meanwhile, ROKR always considers that “Quality is the priority”. With an excellent Research & Development team, more and more awesome designs are born. Those products are quite popular all over the world. Also, ROKR offers the opportunity to customise the products.

Production Process

ROKR’s parent brand Robotime has a large factory covering an area of 23,000 square meters, which provides more than 150 production equipment and 12 production lines. It passed the ISO9001 quality system certification in 2012, became a GMC global manufacturer in 2014, passed the FSC international ecological and environmental protection certification, and became a BSCI European certification enterprise in 2015, and passed the Disney comprehensive management system certification. Besides, we have dozens of patents such as global invention, national invention, utility model, and appearance, etc.

Production Process

ROKR’s parent brand Robotime has a large factory covering an area of 23,000 square meters, which provides more than 150 production equipment and 12 production lines. It passed the ISO9001 quality system certification in 2012, became a GMC global manufacturer in 2014, passed the FSC international ecological and environmental protection certification, and became a BSCI European certification enterprise in 2015, and passed the Disney comprehensive management system certification. Besides, we have dozens of patents such as global invention, national invention, utility model, and appearance, etc.

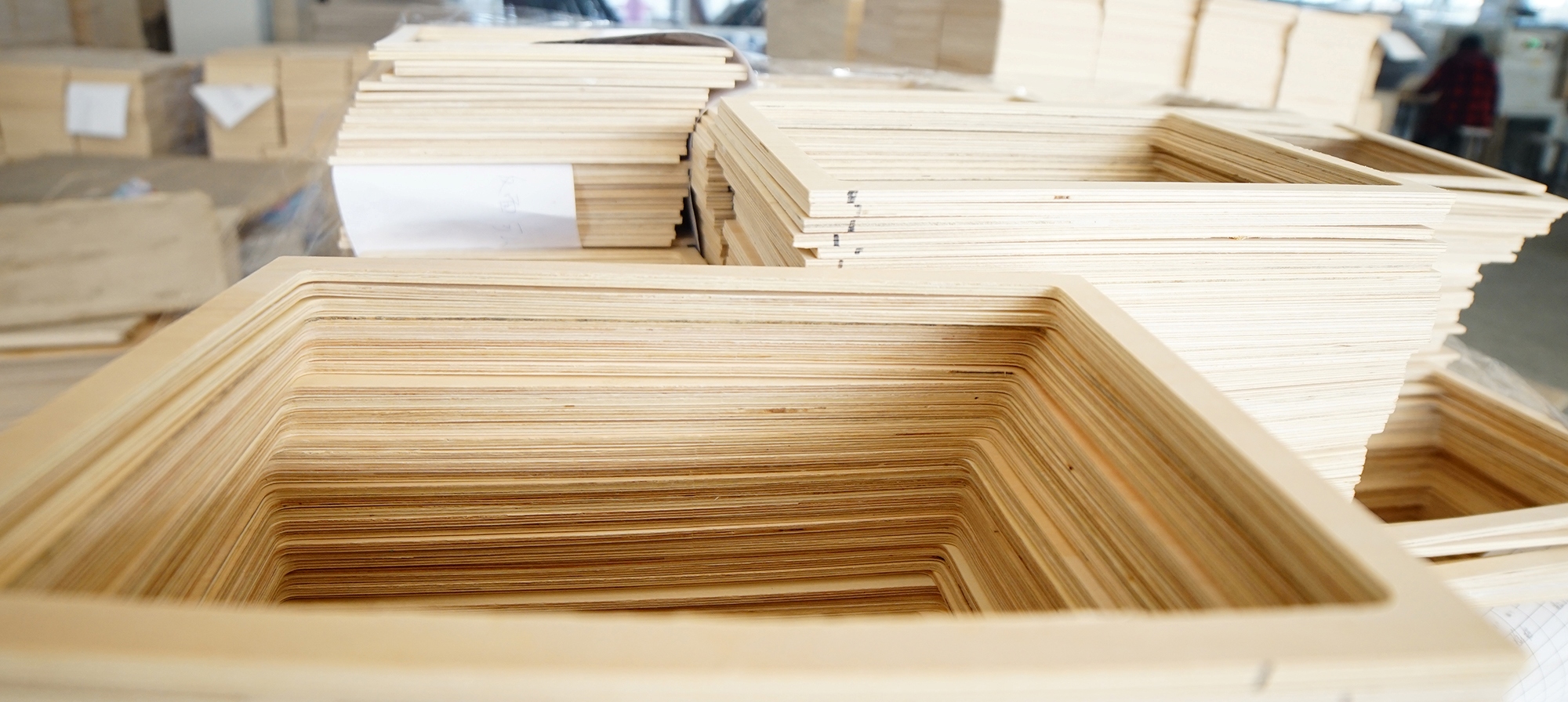

Raw Materials Processing

Basswood veneering & Veneer core manufacturing:

Producing high-quality plywood is dependent on having a consistent and dependable supply of raw materials. In order to achieve this, it is essential to have a reliable quality and stable supply of raw materials. Fortunately, our company’s raw material processing plant is well-equipped to provide the most solid guarantee for this. With our advanced machinery and skilled staff, we are able to efficiently and effectively process raw materials, ensuring a consistent supply of high-quality materials for our plywood production. This allows us to deliver top-quality plywood products to our customers, meeting their specific needs and exceeding their expectations.

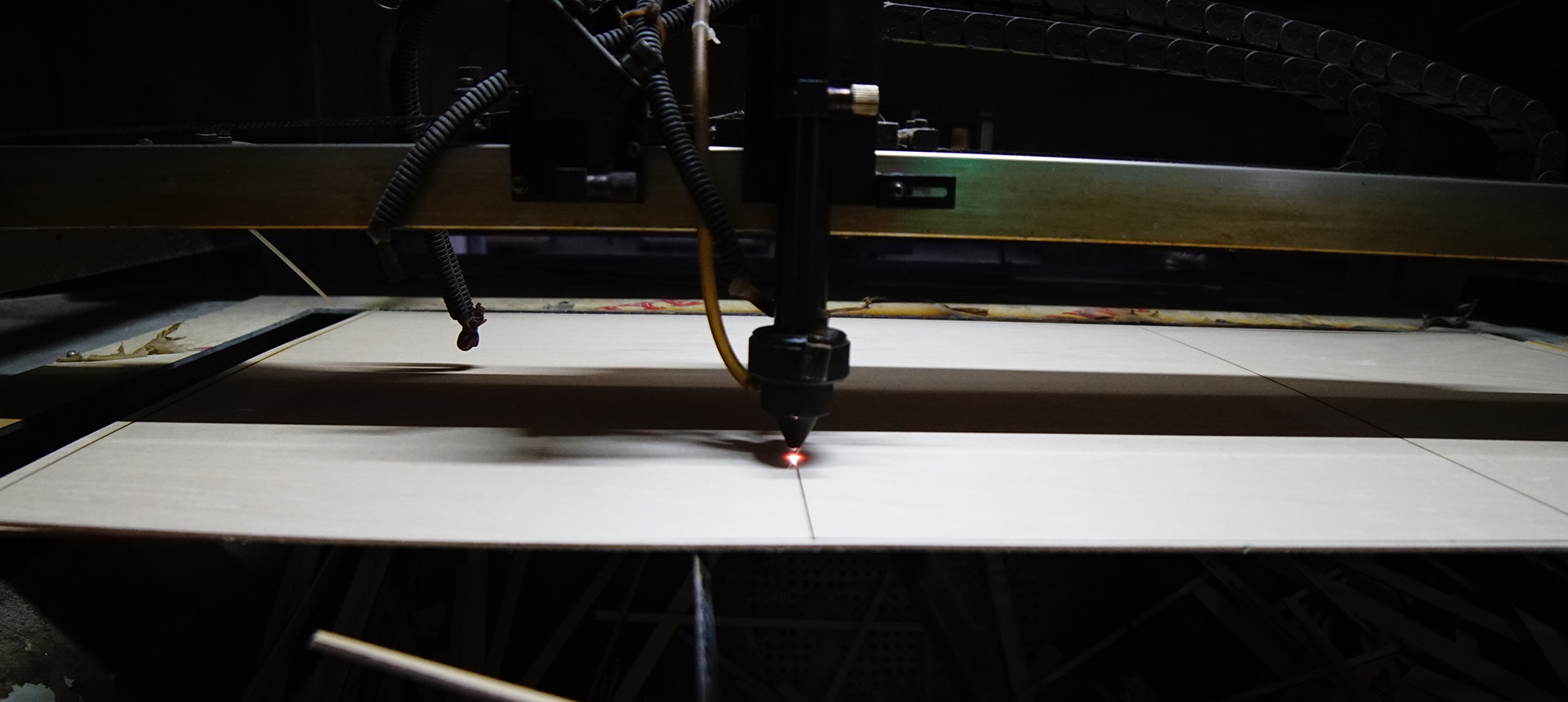

Plywood Production

The quality inspection process of raw materials before stamping is critical to ensure that the finished product meets the required standards. One crucial step in this process is conducting a thickness and moisture test of the raw materials. This test is typically carried out using a micrometer screw, a clamping machine, and a moisture tester. Once the test is complete, the raw materials are sorted and filled to ensure that only qualified materials are used.

In terms of glue, our company prioritizes stability, which is why we only use glue that conforms to the EO standard, with a maximum permissible concentration of 0.05 parts per million (ppm). To verify this, the glue is subjected to laboratory testing to ensure that it meets the required standards. By following these rigorous quality control measures, we can guarantee that the final product is of the highest possible quality.

Professional Team

We have a professional team that integrates design, production, sales, and operation. Among them, 103 designers come from famous universities. With advanced design concepts full of creative passion and rich practical experience, we have gained high recognition and

103 Experienced designers

Top university members

300+ Patents

Professional Team

We have a professional team that integrates design, production, sales, and operation. Among them, 103 designers come from famous universities. With advanced design concepts full of creative passion and rich practical experience, we have gained high recognition and reputation among our customers.

103 Experienced designers

Top university members

300+ Patents

Recognization

2005

5 successful applications of the Robotics patent.

2006

Won a gold award in CAS Venture Competition.

2008

Won a gold award in CTA Innovation Competition.

2011

Won an award in The Toy Association's puzzle toy competition.

2014

Gained FCS Certification.

2015

Gained BSCI Certification.

Sales Channel

As one of the few cultural and creative overseas brands, we currently have a global sales network, including online channels dominated by Amazon and AliExpress, ranking among the Top 3 industry categories all year round; There are also world mainstream offline retail platforms such as Kmart, Hobbytown and Target. It is estimated that by 2023, 10000 offline stores and landmark city flagship stores can be achieved.

ROKR’s products sell well worldwide, including dozens of supermarkets, gift stores, bookstores, and various circulation channels in China, including M&G SHOP, Eslite Bookstore, Fang Suo Commune, Kawaii, and so forth. It covers Sam’Club, Hasbro, Toysrus, Target, GameStop, Kmart, and other large international enterprise partners, reaching 3000+ stores worldwide.

Partners

Lazada is Southeast Asia’s leading online shopping platform, offering a wide range of products from electronics to fashion and groceries. With user-friendly interfaces and secure transactions, Lazada provides convenient and reliable shopping experiences for millions of customers across the region.

Lazada is Southeast Asia’s leading online shopping platform, offering a wide range of products from electronics to fashion and groceries. With user-friendly interfaces and secure transactions, Lazada provides convenient and reliable shopping experiences for millions of customers across the region.

Kikkerland Design Inc. is a New York-based company renowned for its quirky and innovative products. Specializing in designing and curating unique items for home, office, and beyond, Kikkerland blends functionality with creativity to offer a diverse range of goods, from kitchen gadgets to stationery and toys. With a focus on clever design and whimsical aesthetics, Kikkerland has garnered a global following, delighting customers with its playful and practical approach to everyday items.

Kikkerland Design Inc. is a New York-based company renowned for its quirky and innovative products. Specializing in designing and curating unique items for home, office, and beyond, Kikkerland blends functionality with creativity to offer a diverse range of goods, from kitchen gadgets to stationery and toys. With a focus on clever design and whimsical aesthetics, Kikkerland has garnered a global following, delighting customers with its playful and practical approach to everyday items.

PLAZA CREATE is a dynamic platform designed to empower creators of all kinds, from artists to entrepreneurs. It offers a diverse range of tools and resources to bring ideas to life, fostering collaboration and innovation. With its user-friendly interface and customizable features, PLAZA CREATE enables users to seamlessly design, develop, and showcase their projects. Whether crafting digital art, launching a startup, or building an online community, PLAZA CREATE provides the necessary infrastructure and support for success.

PLAZA CREATE is a dynamic platform designed to empower creators of all kinds, from artists to entrepreneurs. It offers a diverse range of tools and resources to bring ideas to life, fostering collaboration and innovation. With its user-friendly interface and customizable features, PLAZA CREATE enables users to seamlessly design, develop, and showcase their projects. Whether crafting digital art, launching a startup, or building an online community, PLAZA CREATE provides the necessary infrastructure and support for success.

HobbyTown is a haven for hobbyists, offering a diverse range of products catering to enthusiasts of all ages and interests. With over 150 locally owned and operated stores across the United States, it’s a go-to destination for model builders, RC enthusiasts, gamers, and more. Whether you’re into remote control vehicles, scale models, trains, drones, or board games, HobbyTown provides a comprehensive selection of products, accessories, and expert advice to fuel your passion.

HobbyTown is a haven for hobbyists, offering a diverse range of products catering to enthusiasts of all ages and interests. With over 150 locally owned and operated stores across the United States, it’s a go-to destination for model builders, RC enthusiasts, gamers, and more. Whether you’re into remote control vehicles, scale models, trains, drones, or board games, HobbyTown provides a comprehensive selection of products, accessories, and expert advice to fuel your passion.

AEON is a Japanese retail corporation operating a diverse range of businesses, including general merchandise stores, supermarkets, and financial services. Founded in 1758 as a kimono silk trader, AEON has evolved into one of Japan’s largest retailers and has expanded globally, with operations in Asia and beyond. Its retail outlets offer a wide array of products, from groceries and clothing to electronics and household goods, catering to diverse consumer needs.

AEON is a Japanese retail corporation operating a diverse range of businesses, including general merchandise stores, supermarkets, and financial services. Founded in 1758 as a kimono silk trader, AEON has evolved into one of Japan’s largest retailers and has expanded globally, with operations in Asia and beyond. Its retail outlets offer a wide array of products, from groceries and clothing to electronics and household goods, catering to diverse consumer needs.

Location

A202 Guohua Building, Chongwen Road, No. 328 Xinghu Street, SIP, Suzhou City, Jiangsu Province, China.

Our hours

9:00 AM – 18:00 PM Monday – Friday

Contact us

Business cooperation: sales@robotime.come Dropshipping cooperation: shop@robotime.com

Location

A202 Guohua Building, Chongwen Road, No. 328 Xinghu Street, SIP, Suzhou City, Jiangsu Province, China.

Our hours

9:00 AM – 18:00 PM Monday – Friday

Contact us

Business cooperation:sales@robotime.come Dropshipping cooperation:shop@robotime.com